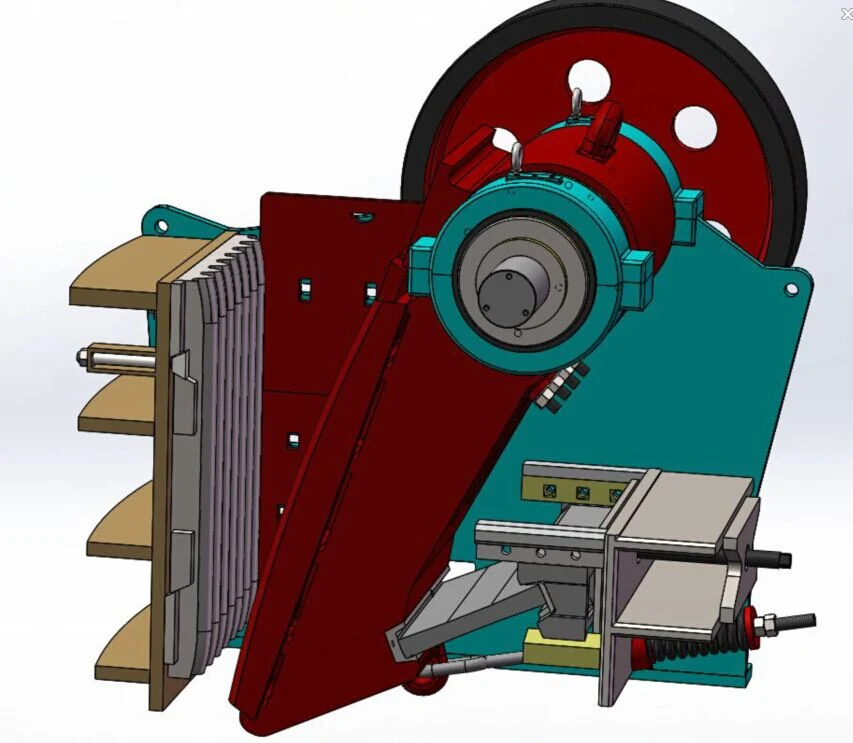

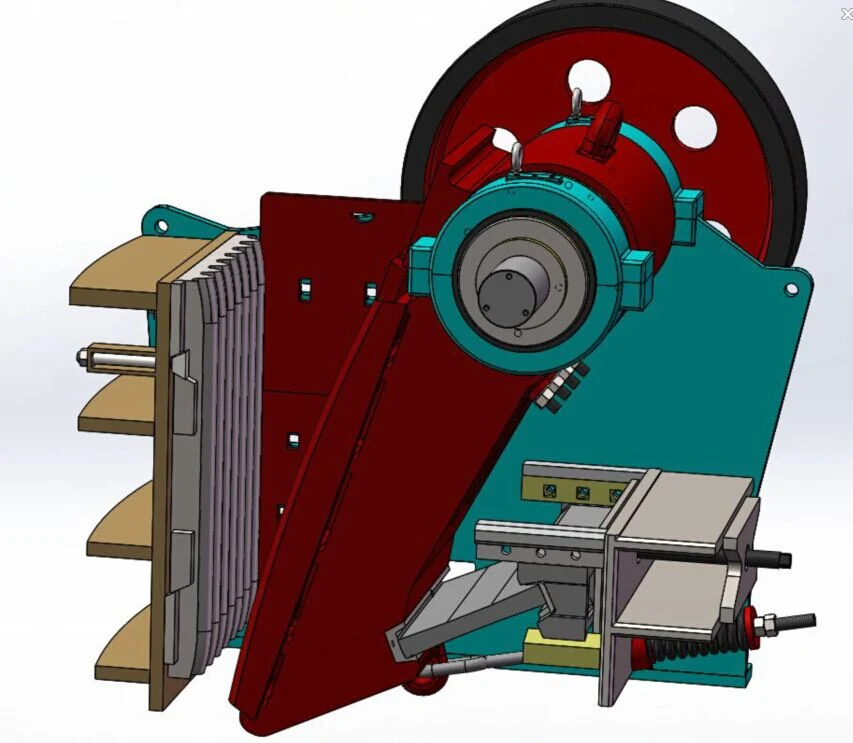

mobile rock crushing machine jaw crusher hammer crusher

Basic Information

Technical data

Introduction

The Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa.

Jaw crusher working principle

The diesel engine drives the eccentric shaft of the jaw crusher through the triangular belt and the trough wheel to make the jaw crusher move reciprocally, so as to crush the material entering the crushing chamber. These final aggregates size can be changed according to clients request, such as 0-10mm, or 0-20mm, or 0-40mm, different final size will be different capacity.

Specification

Features

Basic Information

| Model | PE250*400 | Test&Installation | Professional Engineer Assigned |

| Condition | New | After Sale Service | Lifelong |

| Input size | PE250*400 | Color | Customized |

| Classification | Primary Crushing machinery | Transportion Package | Export standard |

| Jaw Plate Material | Mn13-Mn18 | Main Shaft Material | 40cr |

| Feeding Opening(mm) | 250*400 | Origin | China |

| Driving Method | Diesel or Electric Drive | Warranty | 18months |

| Delivery time | 20days | HS Code | 8474209000 |

Technical data

| Max feeding size(mm) | 210 |

| Feeding Opending size(mm) | 250*400 |

| Discharging opening size(mm) | 10-60 |

| Capacity(tph) | 5-21 |

| Power(kw) | 6p-15kw |

| Dimension(mm) | 1300*1090*1270 |

| Machine includes | Jaw crusher,diesel engine |

| Power supply | engine |

| Final aggregate size(mm) | 0-40mm (alternative) |

Introduction

The Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. The Jaw Crusher is suitable for primary and secondary crushing all kinds of minerals and rocks with compressive strength less than 320 MPa.

Jaw crusher working principle

The diesel engine drives the eccentric shaft of the jaw crusher through the triangular belt and the trough wheel to make the jaw crusher move reciprocally, so as to crush the material entering the crushing chamber. These final aggregates size can be changed according to clients request, such as 0-10mm, or 0-20mm, or 0-40mm, different final size will be different capacity.

Specification

| Model | Feeding size (mm) | Output size (mm) | Capacity (t/h) | Motor powder (kw) | Dimension(mm) |

| PE150*250 | ≤130 | 15-45 | 1-4 | 5.5 | 720*660*850 |

| PE200*300 | ≤150 | 15-50 | 4-6 | 7.5 | 910*750*990 |

| PE200*350 | ≤180 | 15-55 | 3-10 | 7.5 | 1000*870*990 |

| PE250*400 | ≤210 | 25-60 | 5-20 | 15 | 1300*1090*1270 |

| PE400*600 | ≤350 | 40-90 | 15-60 | 30 | 1730*1730*1630 |

| PE500*750 | ≤425 | 50-100 | 40-110 | 55 | 1980*2080*1870 |

| PE600*750 | ≤500 | 150-200 | 80-240 | 55 | 2070*2000*1920 |

| PE600*900 | ≤500 | 60-125 | 90-180 | 55 | 2190*2206*2300 |

| PE750*1060 | ≤630 | 60-150 | 110-380 | 110 | 2660*2430*2800 |

| PE800*1060 | ≤640 | 640 | 130-190 | 110 | 2710*2430*2800 |

| PE900*1200 | ≤750 | 110-165 | 220-450 | 132 | 3380*2870*3330 |

| PE1000*1200 | ≤900 | 110-185 | 315-500 | 132 | 3480*2876*3330 |

| PE1200*1500 | ≤950 | 115-195 | 400-800 | 220 | 4200*3300*3500 |

| PE1500*1800 | ≤1200 | 135-225 | 500-1000 | 280 | 5160*3660*4248 |

| PEX150*750 | ≤120 | 10-40 | 8-25 | 15 | 1200*1530*1060 |

| PEX250*750 | ≤210 | 15-50 | 15-35 | 22 | 1380*1750*1540 |

| PEX350*750 | ≤300 | 15-50 | 18-40 | 30 | 1450*1920*1540 |

| PEX250*1000 | ≤210 | 15-60 | 15-60 | 30 | 1560*1950*1390 |

| PEX250*1200 | ≤210 | 15-60 | 20-60 | 37 | 2140*1660*1500 |

| PEX300*1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2720*1950*1600 |

Features

- simple structure performance with lower diesel power,easy maintaince

- long service life and high work efficiency

- high capacity,less costly and easy to install

- First-class technology, reliable customer service

- High crushing ratio, even output granularity

- Jaw crusher have flexible capacity, you can adjust the output size from 10mm to 40mm to meet your own final aggregates size requirements

- High reliability, low investment,lower noise,low investment